A Engineering Consulting Firm

engineering assessment • mechanical design • prototyping • product development management services

A Engineering Consultancy Firm

design research • engineering assessment • prototyping • product development management services

How can we help you With Your Engineering Design?

Experience & Talent to Tackle Your Unique Engineering Challenges

At Affinity for Mechanical Design, we understand that building manufacturing systems are complex, requiring input from highly skilled mechanical engineering experts. That is why we developed design and consulting services that can assist you in solving any engineering issue that may be holding your company back.

Your company has lost valued engineers and talented designers during Covid

You rather focus the budget on product development than a large-scale engineering department

Your design department needs out-of-the-box engineers who are innovative

You want an engineering consultant who can take your product from conception to full production

Collaborative Mechanical Engineering Design

At Affinity for Mechanical Design, our goal is to facilitate our customer’s innovation without limits. So, we’ve worked to master all the core technologies that your new manufacturing idea might require for success – from design software to prototyping to finished products to packaging, and everything in between. This collaboration, in turn, allows us to partner with customers and ensure success.

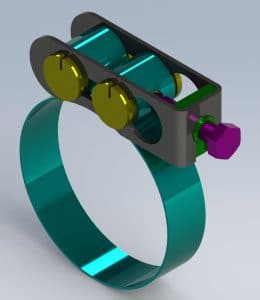

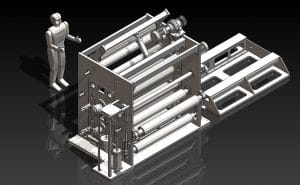

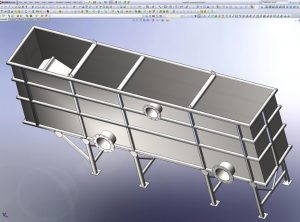

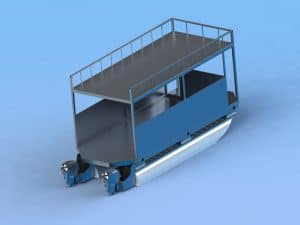

CAD / SolidWorks

Concept Design

Prototyping

Manufacturing

Production

Packaging

Engineered for Success

One of our key goals is not just to assist in designing and building your product, but making sure it is built on-time and at costs that fit your business model.

Our philosophy is simple

- Assist you with creating or finalizing a concept

- Guide you through the development cycle

- Maximize the product user experience

- Ensure product functionality

- Design a manufacturable product

- Maximize your product’s profitability

- Enjoy the satisfaction and privileges that comes from success!

4 Steps to a High Performance Design Process

We have made countless major corporations profitable, but now we want to bring these successes to companies and individuals who want their piece of the pie!

We believe your success is our success. Email us today to discuss your project with one of our experts during a free consultation.

After the consultation, we move to the most critical of step in any design, to analyze the concept of a project. This is the time where we delve deep into our customer’s needs to understand even the smallest detail of what the project entails. This time of extreme communication and mutual understanding is key to resolving issue before a single mouse click is made. Affinity for Mechanical Design spends significant time and effort during this phase to eliminate design flaws before the exist.

When our clients agree with our mutually understood concepts and goals, then we have a rock-solid project concept analysis to start with. Of course, every project will require some modifications and that leads us to our next high performance design process phase – the Design & Progress Communications phase.

Once a project concept has been thoroughly and mutually understood, Affinity for Mechanical Design begins the work of actually engineering the project. During this time, we go to extreme lengths to ensure that the customer understands and agrees with the progress of the design. This “No Drama, No Surprise” process, affords smooth and steady progress of the project in addition to keeping everyone informed.

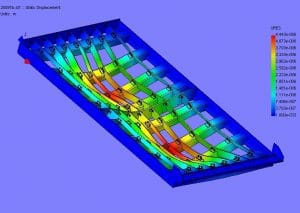

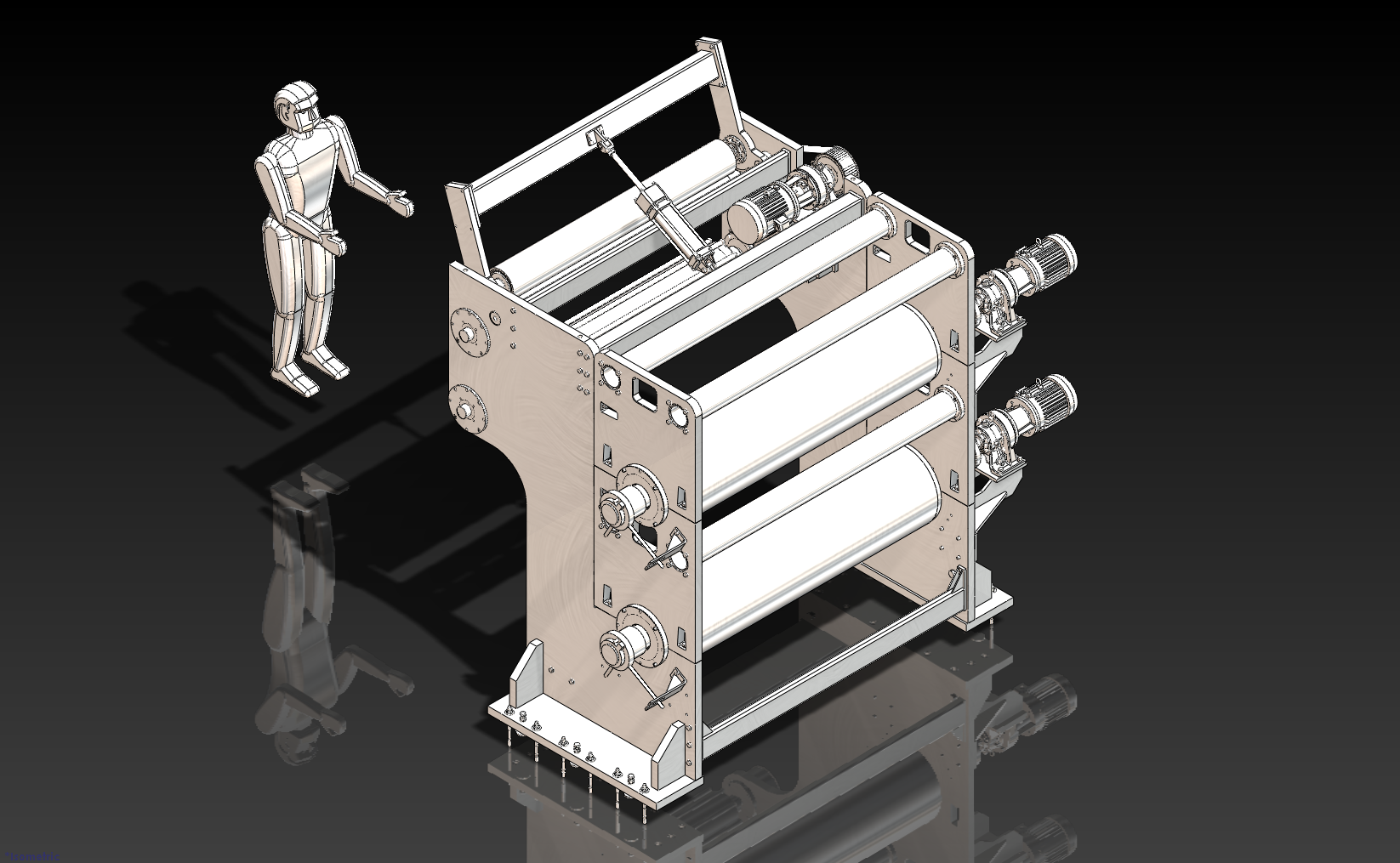

Utilizing 3D solid modeling we can easily and visually communicate mechanical issues and engineering changes required to resolve problems long before the prototype or first piece of material is cut.

Nothing brings more enjoyment than the successful completion of one’s work and seeing it perform with excellence.

We once had a major client with a $125k design project budget. During the project concept analysis, they presented a very complicated system. However, during the design phase I came up with a greatly simplified design that met all the client’s criteria. When the $20k prototype was made and functioned perfectly, the client was stunned and extremely satisfied with the $100k project savings. They manufactured hundreds of units and installed them in their manufacturing plants all across America. Affinity for Mechanical Design made significantly less on the project but the machine we designed was extraordinary. And being extraordinary is what we are all about.

While great end results are enjoyable, Affinity for Mechanical Design has created a system that creates client satisfaction throughout our entire process. Affinity for Mechanical Design’s work ethic, honesty, design transparency, cooperative design process and our innovative and intelligent mechanical designs are all utilized to derive maximum satisfaction to everyone involved.

A smooth path from concept to completion

Experience in numerous industries

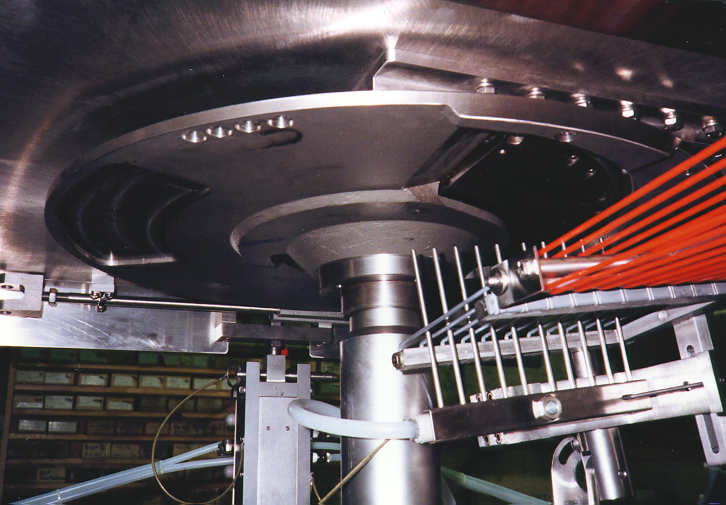

Affinity for Mechanical Design has decades of design and engineering consulting experience in numerous industries from packaging, mining, manufacturing and food processing to product design, medical products and machinery. Creating what others can’t even imagine! Any great engineer can modify things that already exists. But Affinity for Mechanical Design has the ability to see and create that which doesn’t exist. Innovation is our specialty. Whether it is a new product or a new machine to manufacture that product, we don’t think out-of-the-box, we throw the box out altogether. We think and design in the space between our ears!Design and engineering consulting project successes

- This enabled us to design and build the world’s fastest remote-control car, decades ago, before any company even manufactured retail 1/4 scale RC cars.

- We developed the 16-axis machine that ground the smallest carbide circuit board drill in history. On a single machine, it not only produced carbide drill bits from start to finish, but it also automatically inspected the finished product and packaged it without a single person touching the bit. This alone reduced scrap for 24% to less that 5%, and Silicon Graphics (Cray Research) bought every drill bit the machine produced. In the end the bit’s manufacturer purchased 12 of the $250,000.00 machines that produced thousands of .018” (or smaller) bits a day.

- We also designed the fastest lunch meat slicer on the planet. This slicer produced 1lb stacks at 1,200 slices a minute! That is 75 stacks of meat per minute. Do the math and figure out the G-forces this machine needed to move a 1lb stack of meat, 5” in just 50 milliseconds! Oh, and the meat stack had to stay intact. And after we finished the one stack machine, we designed a two-stack model that produced 2,400 slices a minute.

- We took a slicer that was purely mechanical, with chains and gearboxes, and completely recreated it into a computer and servo motor controlled “speed demon” for Subway! The company that manufactured the slicer, said that this machine “Revolutionized the meat slicing industry!” Subway had to slow the slicer down until they upgraded their entire processing and packaging line to match the slicer’s capabilities. This sort of performance is not good modifications, it is true innovation!